High-Balance Film Resistor

All images by Eric Schlaepfer & Windell H. Oskay

This higher-balance film resistor, about 4 millimeters in diameter, is manufactured in substantially the exact same way as its low-cost carbon-movie cousin, but with exacting precision. A ceramic rod is coated with a fantastic layer of resistive movie (thin metal, metal oxide, or carbon) and then a flawlessly uniform helical groove is machined into the film.

In its place of coating the resistor with an epoxy, it’s hermetically sealed in a lustrous minor glass envelope. This tends to make the resistor more sturdy, suitable for specialised cases this kind of as precision reference instrumentation, exactly where prolonged-term security of the resistor is critical. The glass envelope presents much better isolation from dampness and other environmental adjustments than normal coatings like epoxy.

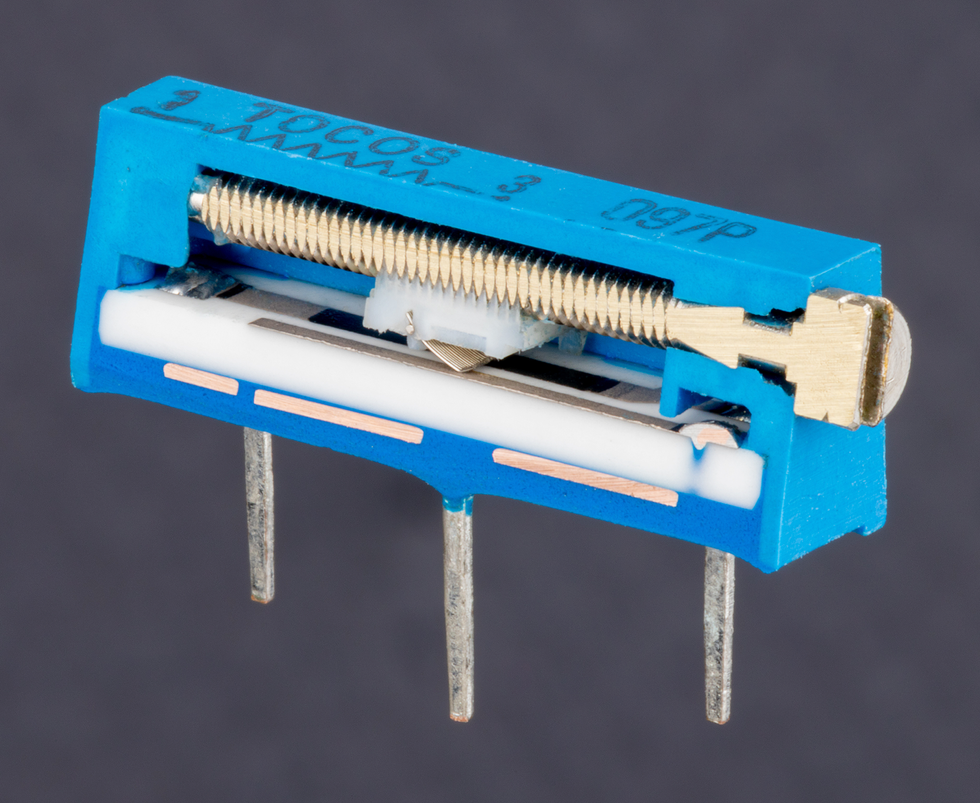

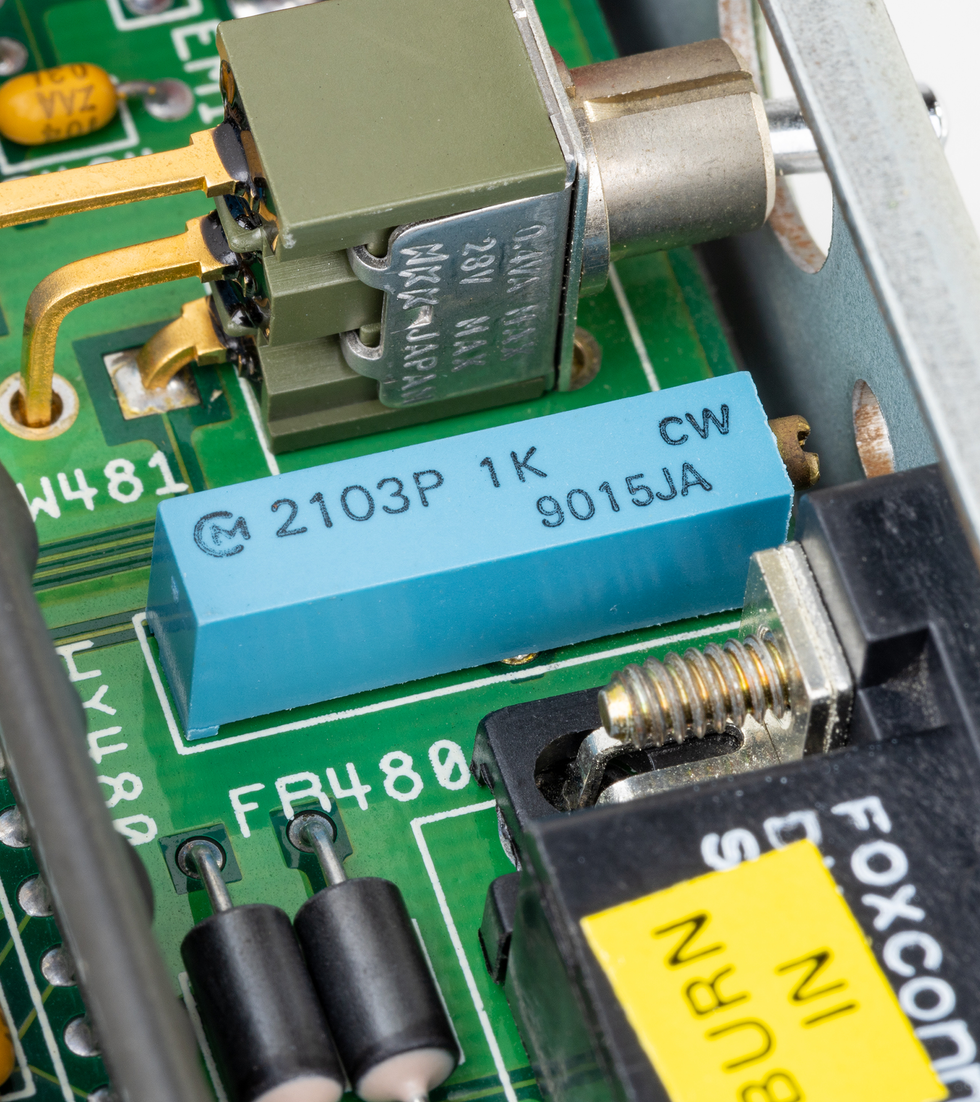

15-Flip Trimmer Potentiometer

It will take 15 rotations of an adjustment screw to go a 15-convert trimmer potentiometer from 1 close of its resistive vary to the other. Circuits that need to have to be altered with fine resolution handle use this variety of trimmer pot as an alternative of the single-convert assortment.

The resistive factor in this trimmer is a strip of cermet—a composite of ceramic and metal—silk-screened on a white ceramic substrate. Monitor-printed metal back links every single conclusion of the strip to the connecting wires. It is a flattened, linear edition of the horseshoe-shaped resistive aspect in solitary-switch trimmers.

Turning the adjustment screw moves a plastic slider together a keep track of. The wiper is a spring finger, a spring-loaded metal make contact with, connected to the slider. It tends to make make contact with involving a steel strip and the picked place on the strip of resistive movie.

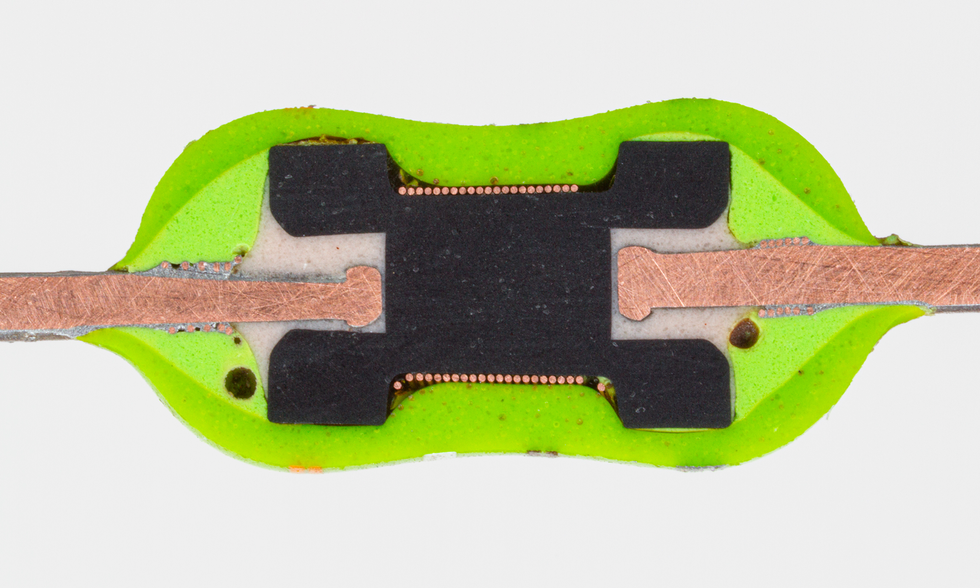

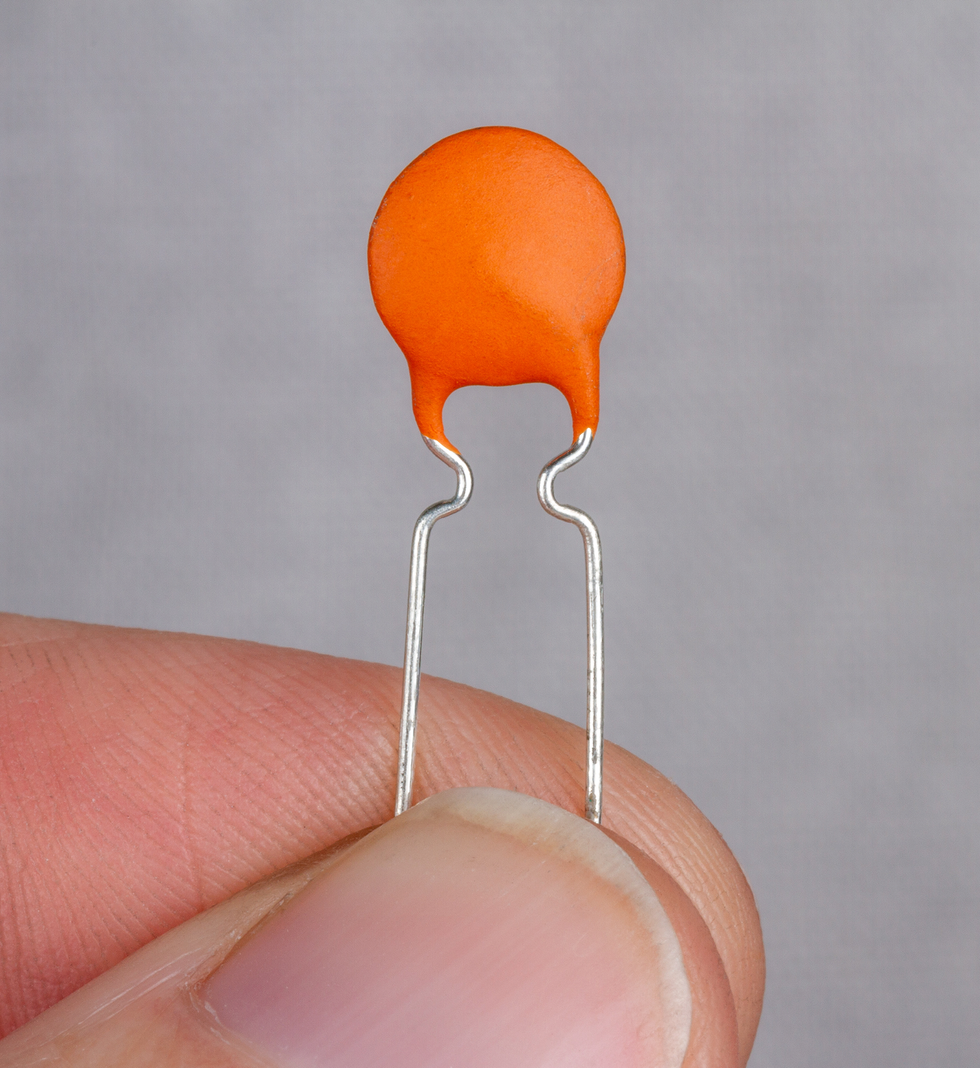

Ceramic Disc Capacitor

Capacitors are fundamental digital parts that retail store electricity in the type of static energy. They are made use of in countless techniques, including for bulk strength storage, to clean out electronic alerts, and as personal computer memory cells. The simplest capacitor is composed of two parallel metallic plates with a hole among them, but capacitors can choose many forms so extensive as there are two conductive surfaces, known as electrodes, divided by an insulator.

A ceramic disc capacitor is a very low-price capacitor that is commonly uncovered in appliances and toys. Its insulator is a ceramic disc, and its two parallel plates are particularly slender metal coatings that are evaporated or sputtered onto the disc’s outer surfaces. Connecting wires are hooked up making use of solder, and the complete assembly is dipped into a porous coating product that dries hard and shields the capacitor from destruction.

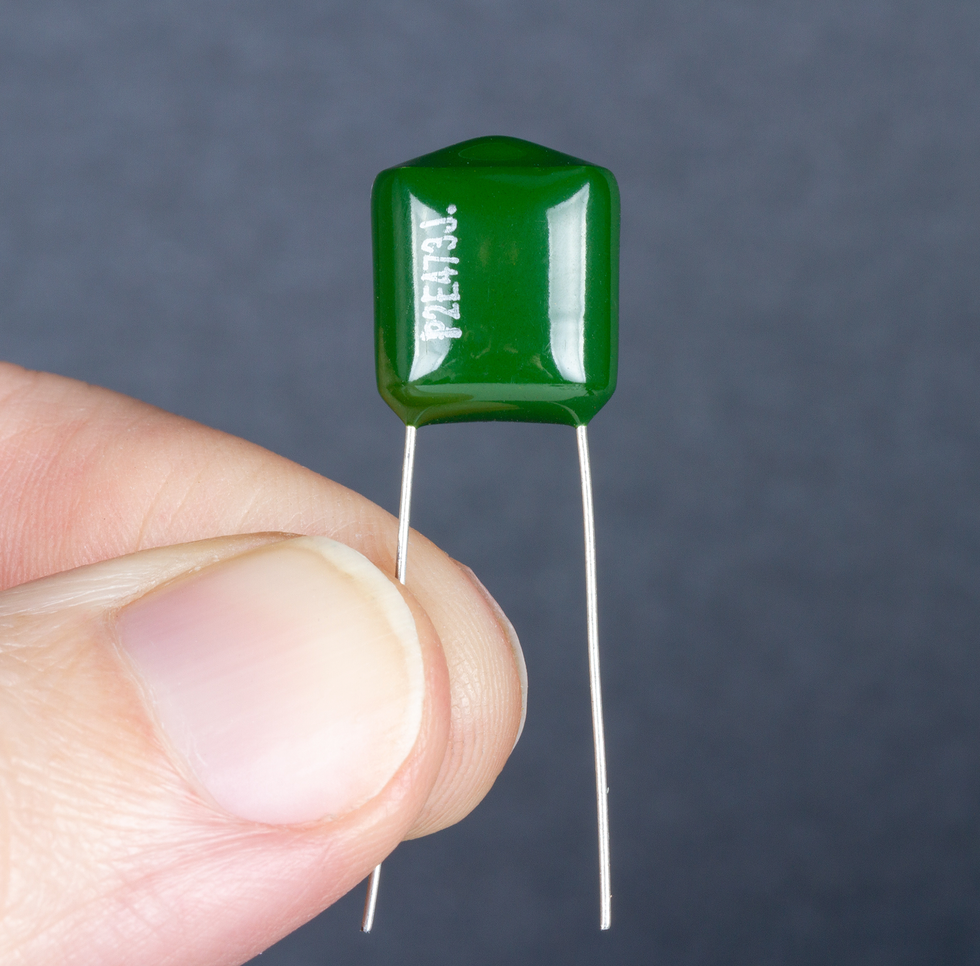

Movie Capacitor

Movie capacitors are regularly found in substantial-excellent audio devices, these types of as headphone amplifiers, file gamers, graphic equalizers, and radio tuners. Their key aspect is that the dielectric product is a plastic film, this sort of as polyester or polypropylene.

The metallic electrodes of this film capacitor are vacuum-deposited on the surfaces of very long strips of plastic film. Right after the prospects are connected, the films are rolled up and dipped into an epoxy that binds the assembly together. Then the done assembly is dipped in a tough outer coating and marked with its value.

Other sorts of film capacitors are produced by stacking flat layers of metallized plastic film, somewhat than rolling up layers of film.

Dipped Tantalum Capacitor

At the main of this capacitor is a porous pellet of tantalum metal. The pellet is manufactured from tantalum powder and sintered, or compressed at a high temperature, into a dense, spongelike sound.

Just like a kitchen area sponge, the resulting pellet has a superior surface area space for each device volume. The pellet is then anodized, making an insulating oxide layer with an similarly high area space. This process packs a large amount of capacitance into a compact product, utilizing spongelike geometry alternatively than the stacked or rolled layers that most other capacitors use.

The device’s beneficial terminal, or anode, is connected specifically to the tantalum steel. The negative terminal, or cathode, is formed by a skinny layer of conductive manganese dioxide coating the pellet.

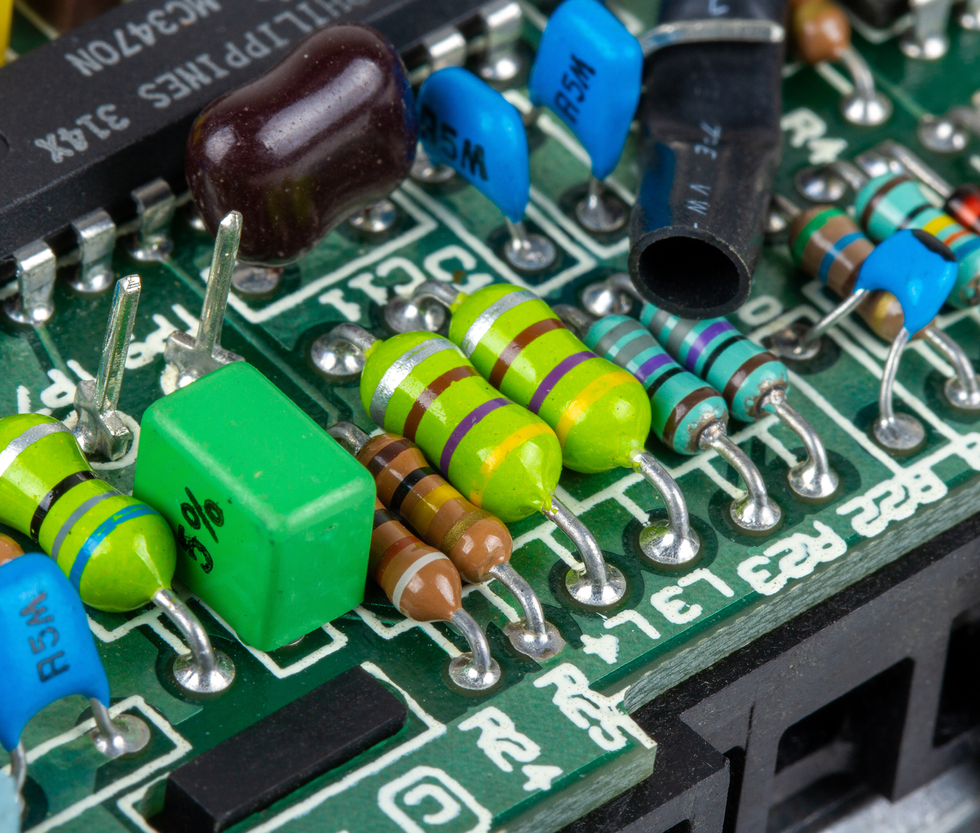

Axial Inductor

Inductors are fundamental digital elements that shop strength in the variety of a magnetic industry. They are utilized, for example, in some types of ability provides to transform between voltages by alternately storing and releasing electrical power. This energy-economical layout can help improve the battery everyday living of cellphones and other portable electronics.

Inductors generally consist of a coil of insulated wire wrapped around a main of magnetic content like iron or ferrite, a ceramic filled with iron oxide. Present-day flowing about the core provides a magnetic area that acts as a form of flywheel for latest, smoothing out alterations in the present-day as it flows via the inductor.

This axial inductor has a selection of turns of varnished copper wire wrapped all around a ferrite form and soldered to copper prospects on its two finishes. It has several layers of defense: a distinct varnish over the windings, a light-weight-environmentally friendly coating about the solder joints, and a hanging inexperienced outer coating to guard the entire component and give a floor for the vibrant stripes that reveal its inductance value.

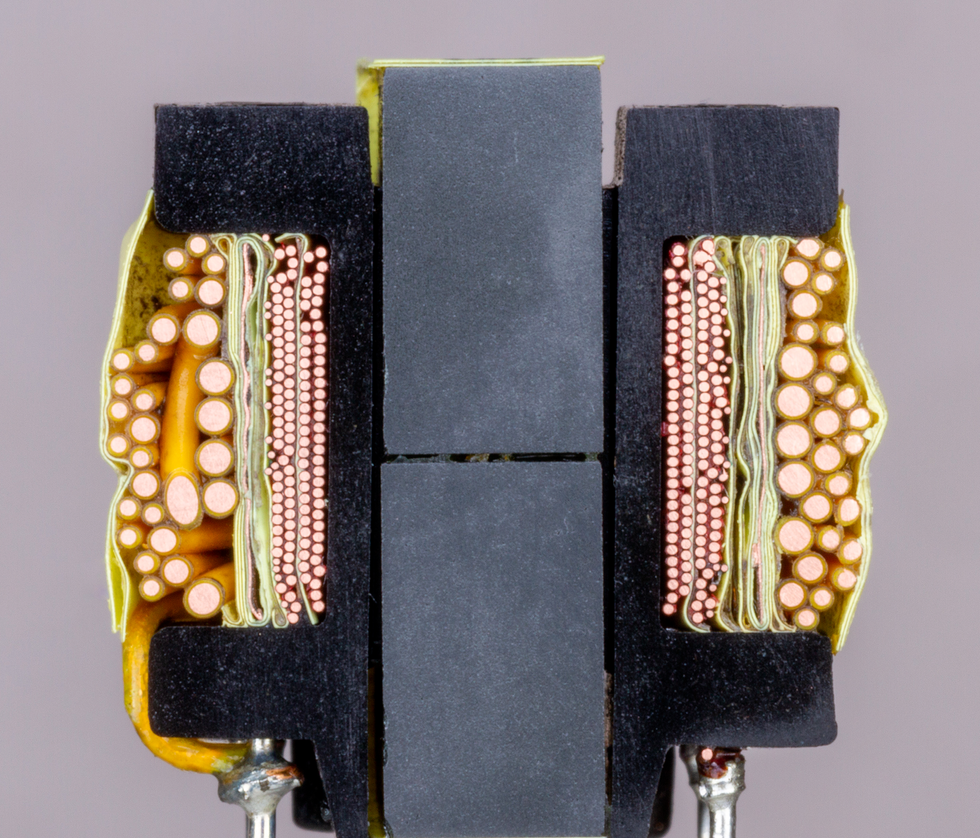

Power Offer Transformer

This transformer has various sets of windings and is utilized in a electric power provide to build various output AC voltages from a solitary AC input these kinds of as a wall outlet.

The compact wires nearer the middle are “high impedance” turns of magnet wire. These windings carry a bigger voltage but a lessen current. They’re safeguarded by numerous levels of tape, a copper-foil electrostatic defend, and a lot more tape.

The outer “low impedance” windings are produced with thicker insulated wire and fewer turns. They tackle a reduced voltage but a higher current.

All of the windings are wrapped all around a black plastic bobbin. Two parts of ferrite ceramic are bonded with each other to type the magnetic main at the heart of the transformer.

From Your Web site Content articles

Related Articles or blog posts All around the World wide web